Press release of Kiel University

New diagnostics and maritime applications for plasma technologies

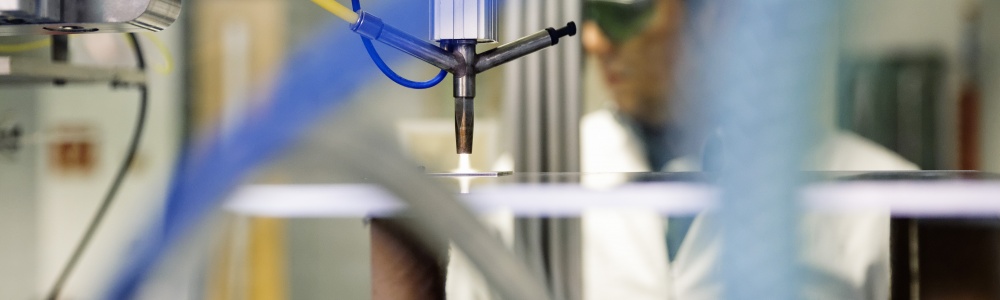

Last week, 35 representatives from science and industry met at Christian-Albrechts-Universität zu Kiel (CAU) to discuss the potential applications of atmospheric pressure plasmas. Such gas discharge plasmas are particularly suitable for coating or cleaning surfaces. Possible fields of application include not only surface technology but also maritime and medical applications. The central prerequisite for this is controllable processes. The focus of the two-day workshop, which brought together participants from all over Germany and Austria, was therefore primarily on the question of special diagnostics for comprehensively analyzing and improving these processes. The workshop was organized by the Anwenderkreis Atmosphärendruckplasma in cooperation with the Institute for Experimental and Applied Physics at CAU.

© Julia Siekmann, CAU

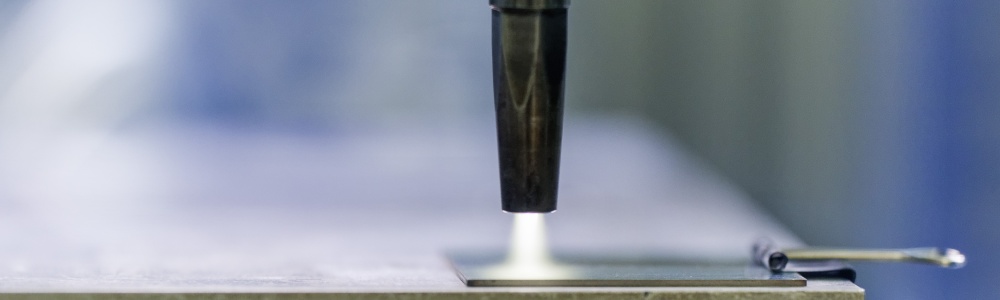

Unique properties characterize plasmas as the fourth state of matter in addition to solid, liquid and gas. The ionized gas mixture conducts electricity and can interact with a magnetic field. If electrical energy or heat is applied, it glows - in the form of thunderstorm lightning or in energy-saving lamps, it becomes visible in everyday life. Such a highly active environment can be used, among other things, to process surfaces. In the optical industry, for example, plasmas are used to provide eyeglass lenses with a nano-thin protective layer.

Vacuum conditions are usually required to carry out such coating processes with plasmas. However, the complex treatment environment is not suitable for all materials and applications. It is less complicated to use so-called atmospheric pressure plasmas. Their pressure corresponds to that of the atmosphere, so they can be applied to normal ambient air. In view of the relatively low gas temperatures, these are also referred to as "cold plasmas".

© Julia Siekmann, CAU

Easy integration into existing production lines

"Processes with atmospheric pressure plasmas can be integrated relatively unproblematically and comparatively inexpensively into existing production plants," emphasizes Dr. Kerstin Horn of the Atmospheric Pressure Plasma User Group. Since 2009, the nationwide exchange platform has been promoting this surface processing technology and bringing together research, plant engineering and application. Typical fields of application for atmospheric pressure plasmas are the coating of materials with corrosion or UV protection or the pretreatment of adhesive, printing and painting surfaces to improve the adhesion of metals or plastics.

The workshop, which took place this week at the Kiel Science Center, focused primarily on methods for optimizing plasma-based processes. "In order to use plasma technologies effectively in industry, we need safe, controllable processes. For this, we need to understand what happens in detail and what the central influencing factors are," said Holger Kersten, professor of plasma technology at CAU and co-organizer of the conference. At the start of the workshop, he presented various diagnostic methods, including a thermal probe developed in his research group, which measures the energy flow between plasmas and surfaces via the change in temperature - one of the key parameters in plasma processes.

© Julia Siekmann, CAU

Also maritime and medical applications

A second focus of the event was on marine applications. Disturbing biofilms form after a short time on surfaces that are in contact with seawater. Anti-fouling coatings applied with plasmas can reduce this fouling. The field of medical applications of atmospheric plasmas is still relatively new. Because of their ambient air applications and comparatively low temperature, they can be used for wound healing and as an alternative treatment method to combat multidrug-resistant germs. "Atmospheric pressure plasmas offer great potential for gentle treatment and small surgical procedures," Jan Benedikt, professor of experimental plasma physics at CAU, highlighted in his presentation. "They react very well with biological tissue and such fluids as are found in cells. What happens at this crucial zone, however, needs more research."

During the workshop, the participants also had the opportunity to visit the laboratories of the Plasma Technology (headed by Professor Holger Kersten) and Experimental Plasma Physics (headed by Professor Jan Benedikt) research groups. In Kiel, plasma physics has long been one of the focal points at the Institute for Experimental and Applied Physics. "CAU is one of the few universities in Germany that supports research and education in plasma physics with its own professorships," says Kersten, underlining the expertise at the Kiel site.